| Table of Contents |

|---|

| Free Best Business Energy Efficiency Practices |

| Fluorescent Lighting |

| Power Factor Correction |

| Air Conditioning |

| Alternative Cooling |

| Motion Controlled Lighting |

| Timers |

| Co-Generation |

Free Best Work Practices

Simple good habits can save you power without being too inconvenient. Your changes in habit and therefore power consumption can be viewed on a building power meter. You should be aiming to keep its average reading as low as possible.

Here are some suggestions of how to keep your total consumption low.

- Train staff to shutdown their computer at the end of each work day

- Instruct staff on how to turn on computer power management options on desktops and laptops

- Instruct staff how to switch on and off the office lighting and to know which switch does what

- Have instructions near printers on how to print in duplex by default

- Use email instead of faxes where possible

- Use email instead of post where possible

- Ask for electronic rather than hard copies of documents

- Don't print emails if possible

- Use the back of scrap papers instead of notepads for personal temporary notes

- Turn off air conditioners, fans and lights when leaving a room

Table of Contents Reference Links

Fluorescent Lighting

The use of fluorescent lighting in great quantities in the workplace suggests that a

greater effort should be placed to make them work as efficiently as possible.

Lighting may contribute up to 50% of your energy costs.

The use of fluorescent lighting in great quantities in the workplace suggests that a

greater effort should be placed to make them work as efficiently as possible.

Lighting may contribute up to 50% of your energy costs.

Consider replace fluorescent tube lighting with LED tube lighting to save about 50% on energy.

LED tube lighting requires a special replacement starter. Sometimes it comes with the tube.

LED tube lighting can last 50,000 hours which should reduce maintenance. LED tubes start instantly.

Fluorescent tubes has a lifespan of 20,000 to 40,000 hours.

Some electronic ballast controller light fittings allow for dimming.

Electronics ballasts operate at a higher frequency of around 40000 cycles per second which reduces human fatigue

from fluorescent lights flickering.

Can I program lighting to work on a 7 day schedule?

Are there any places where timer switches would be suitable e.g. security lighting, sign lighting?

Would motion sensors be useful for lighting certain areas e.g. kitchens, hallways, entrance ways, bathrooms?

Can daylight sensors be used to control certain lighting e.g. outdoor security lighting?

Can dimming be used where natural light comes in from outside in variable quantities?

Are light switches suitably divided to suit individual requirements e.g. avoid single switches controlling the whole floor when that is not always needed

Do staff know what switches are for lighting? Provide good labelling at switches.

Are the covers over the lights cleaned periodically?

Note: Electrical work involving ballasts should be performed by a qualified electrician.

There are same sized LED tube replacements now available that use just 16 watts for a 4 foot fitting (around 50% saving) and require no ballast. To retrofit an existing light, bypass the ballast and install the LED-fluorescent in the same fitting. LED fluorescent have a 50000 hour plus life span. They cost initially is high $ 70 US but consider your return on investment in under 2 years.

| Tubes in fitting | Ballast type | Tube rating watts | Total lumens light | Running watts | Year running cost for 12 hrs/day at $0.25 kWh | Assume 200 light fittings per floor for 100 persons |

|---|---|---|---|---|---|---|

| 2 | magnetic | 34 | 4660 | 72 | $78.84 | $15,768 |

| 2 | electronic | 32 | 4680 | 48 | $52.56 | $10,512 |

| 2 | LED (ballast not needed) |

18 | 3200 | 36 | $39.42 | $7,884 |

| Saving | $39.42 | $7,884 |

Suggestions: Remember to turn off lights when you leave a room. Invest in timers or motion sensors for security lighting applications.

Related Sections: Measurement Power Factor Correction Incandescent Lights vs Compact Fluorescent Lights Halogen Lights vs LED Lights Motion Controlled Lighting Timers

Local Assistance: Light Energy Calculator

References for further information 1 28 29 30 31 32

Table of Contents Reference Links

Power Factor Correction

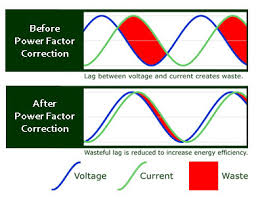

Power factor is a relationship between your electrical loads and how well they

interact with your electrical supplier. If your electric device changes the

timing of the voltage or current waveform or causes feedback back to the

electricity supplier you pay extra.

Power factor is a relationship between your electrical loads and how well they

interact with your electrical supplier. If your electric device changes the

timing of the voltage or current waveform or causes feedback back to the

electricity supplier you pay extra.

Electric strip heaters and incandescent lights use electricity without corruption and have a power factor of 1. Electric motors and fluorescent lights without power factor correcting (PFC) capacitors create reactive loads, giving them a power factor less than 1. Motors can have capacitors at their electrical input to compensate for the reactive load. Motors controlled with inverter style power supplies usually have good power factor. Electronic fluorescent ballast can have greater than 0.98 power factor. An alternative is to make sure each fluorescent lighting circuit has matching power factor correcting capacitors fitted. This can be specified at installation or retrofitted by an electrician. Consider retrofitting electronic ballasts for lighting with modern fluorescent tubes instead, you get the same light with less power used. Good power measurement devices will tell you if you have a reactive load. For large industry, real time monitoring of the building or site and correction in single or 3 phase is possible. This is like adding capacitors to the mains to compensate for reactive loads in real time. If in doubt measure it. The return on investment can be 2-3 years.

Suggestions: Buy LED light fittings that do not need power factor correction. Check the specification of devices with motors for power factor value (0.9 to 1.0 is desireable). Adding a modern solar inverter includes power factor correction. Motors with inverter controllers usually do not need power factor correction.

Related Sections: Fluorescent Lighting Measurement

References for further information 33 34

Table of Contents Reference Links

Air Conditioning

Efficiently using electricity within a building has an added benefit of reducing the amount

of cooling required. It is more efficient to cool a building with a low

external ambient temperature. New systems are now available to run cooling

systems overnight that create chilled water on off peak electricity using large storage

tanks for use during the day. This is then used in the day for chilled water

distribution for the buildings cooling systems. The peak tariff is reduced by 95%.

Having a single cooling centre with piping distribution systems to neighbouring

building can save on capital costs. This system is now in use at some

Australian Universities.

Efficiently using electricity within a building has an added benefit of reducing the amount

of cooling required. It is more efficient to cool a building with a low

external ambient temperature. New systems are now available to run cooling

systems overnight that create chilled water on off peak electricity using large storage

tanks for use during the day. This is then used in the day for chilled water

distribution for the buildings cooling systems. The peak tariff is reduced by 95%.

Having a single cooling centre with piping distribution systems to neighbouring

building can save on capital costs. This system is now in use at some

Australian Universities.

Suggestions: Minimise electrical load to reduce cooling load.

Related Sections: Work Fluorescent Lighting 80 Plus Power Supplies Timers Co-Generation Insulation Virtual Computing with Storage Area Network Thin Client vs. Desktop Energy Star 4 BIOS settings Insulation Draft Stopper Co-Generation

Local Assistance: Appliance Energy Calculator

References for further information 35 133 134

Table of Contents Reference Links

Alternative Cooling

Some novel ways of dealing with cooling include venting hot air straight out of the building

rather than cooling it down again and recycle the air. If the external

temperature is lower that the internal temperature then heat exchanging with a

large external body of existing water is possible for cheaper cooling. Data

centres which run 24/7 can be large user of air conditioning. Careful ducting

of air through the data racks can reduce overall cooling costs. Virtual

Computing is an option to reduce the heat from data centres by a factor of 7:1.

Virtual machines can be represented on different physical computers as they are

simply a file held on central storage. Having the VM links move on to fewer

servers at quiet times allows for shutting down idle servers

automatically.This will reduce night and weekend power consumption and the air conditioning load.

Some novel ways of dealing with cooling include venting hot air straight out of the building

rather than cooling it down again and recycle the air. If the external

temperature is lower that the internal temperature then heat exchanging with a

large external body of existing water is possible for cheaper cooling. Data

centres which run 24/7 can be large user of air conditioning. Careful ducting

of air through the data racks can reduce overall cooling costs. Virtual

Computing is an option to reduce the heat from data centres by a factor of 7:1.

Virtual machines can be represented on different physical computers as they are

simply a file held on central storage. Having the VM links move on to fewer

servers at quiet times allows for shutting down idle servers

automatically.This will reduce night and weekend power consumption and the air conditioning load.

Suggestions: Consider Virtual computing for new projects and consolidate existing servers. Consider using outside air exchange more if its temperature is low. Consider cloud computing to remove computing heat sources from the building.

Related Sections: 80 Plus Power Supplies Virtual Computing with Storage Area Network Thin Client vs. Desktop Energy Star 4 BIOS settings Co-Generation

References for further information 36 133 134

Table of Contents Reference Links

Motion Controlled Lighting

Consider how your business lighting is fitted if people are present only part of the

time. The use of motion sensors can reduce the time these lights need to

operate. Places where this is possible include meeting rooms, storerooms,

walkways, entrance ways, bathrooms and even general work areas. These sensors

can be a part of a large building control system. The sensor type should suit

the operating situation and the options include infrared, ultrasonic and

microware. Presence sensors are very sensitive motion detectors that can work

in an office environment to detect if people are present and thereby keeping

the lights on. Infrared and ultrasonic sensors are better at detecting greater

movement which suits path and security lighting control. Light fittings can be

built with the sensor incorporated. Stand alone sensors can control a single

light or a series of electrically connected lights. Solar power lights can be

bought with motion sensors built in which improves efficiency and required no

mains wiring. Lighting run time can be 5 seconds to 15 minutes with self

resetting of the timer if movement is detected again.

Consider how your business lighting is fitted if people are present only part of the

time. The use of motion sensors can reduce the time these lights need to

operate. Places where this is possible include meeting rooms, storerooms,

walkways, entrance ways, bathrooms and even general work areas. These sensors

can be a part of a large building control system. The sensor type should suit

the operating situation and the options include infrared, ultrasonic and

microware. Presence sensors are very sensitive motion detectors that can work

in an office environment to detect if people are present and thereby keeping

the lights on. Infrared and ultrasonic sensors are better at detecting greater

movement which suits path and security lighting control. Light fittings can be

built with the sensor incorporated. Stand alone sensors can control a single

light or a series of electrically connected lights. Solar power lights can be

bought with motion sensors built in which improves efficiency and required no

mains wiring. Lighting run time can be 5 seconds to 15 minutes with self

resetting of the timer if movement is detected again.

Suggestions: Assess the building for where motion sensors can be fitted. A timer can be used to turn off the light circuit after hours to save on the motion sensor running cost. Building management systems can coordinate lighting use on a broad scale.

Related Sections: Timers Fluorescent Lighting

Local Assistance: Light Energy Calculator

References for further information 37 38

Table of Contents' Reference Links

Timers

Timers can be use to control all sorts of electrical loads and to therefore save power and

money. They can be placed in power distribution boards or on individual power

points. Basic timers can be purchased for less than $10. They can be programmed

to operate in daily, weekly and yearly schedules. Consider using a timer on any

appliance that uses over 10 watts as you should balance the potential savings

against the cost of the timer. Lighting can be controlled by timers both for a

fixed time or a day or night sensor. Fixed wall mounted timers can be set from

0 to 15 hours for uses such as stairway lighting, classroom lighting and

exhaust fan operations. Existing wall switches can be replaced with switch and

timer devices. Exterior walkways or security lights can be controlled by day

night sensors. Signage lights and interior lights can be controlled by timers at

the power distribution board. Consider using a timer on an appliance where the

standby power consumption is significant. When the operating hours of equipment

is known, then timers for out of hours can be considered on items such as

printers and photocopiers for example. Timers can be used for user activated

short periods e.g. Spa or sauna heating and spa air bumbles. Installing a timer

on your battery charging device gives the added benefit of preventing

overcharging. Some digital timers that cost around$15 can be used for set

countdown times up to 24 hours from one button which can be either plugged into

a power point or hard wired and mounted on the wall. Consider using a digital

timer to control cooling or heating for when people are present.

Timers can be use to control all sorts of electrical loads and to therefore save power and

money. They can be placed in power distribution boards or on individual power

points. Basic timers can be purchased for less than $10. They can be programmed

to operate in daily, weekly and yearly schedules. Consider using a timer on any

appliance that uses over 10 watts as you should balance the potential savings

against the cost of the timer. Lighting can be controlled by timers both for a

fixed time or a day or night sensor. Fixed wall mounted timers can be set from

0 to 15 hours for uses such as stairway lighting, classroom lighting and

exhaust fan operations. Existing wall switches can be replaced with switch and

timer devices. Exterior walkways or security lights can be controlled by day

night sensors. Signage lights and interior lights can be controlled by timers at

the power distribution board. Consider using a timer on an appliance where the

standby power consumption is significant. When the operating hours of equipment

is known, then timers for out of hours can be considered on items such as

printers and photocopiers for example. Timers can be used for user activated

short periods e.g. Spa or sauna heating and spa air bumbles. Installing a timer

on your battery charging device gives the added benefit of preventing

overcharging. Some digital timers that cost around$15 can be used for set

countdown times up to 24 hours from one button which can be either plugged into

a power point or hard wired and mounted on the wall. Consider using a digital

timer to control cooling or heating for when people are present.

Suggestions: Learn the operating hours of electrical devices and consider using a timer. Set room air conditioner/s to start times by a seasonal pattern.

Related Sections: Measurement Pool Pumps Air Conditioning Work Lighting Television Linear vs. Switched Mode Power supplies

Local Assistance: Appliance Energy Calculator

References for further information 39 122 149

Table of Contents Reference Links

Co-Generation

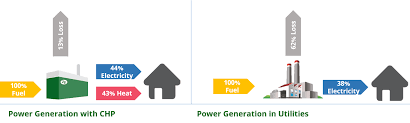

This is the process of using input energy twice, once for electricity; and then the second time for heat. The heat is usually used for hot water or room heating, so the electricity generated first is the bonus. This can be practically achieved by using natural gas as the input, running it through a gas powered electric generator first and then using the heat for hot water or room heating. A small scale example is from Honda who created a cogeneration device that contains a 1 kW gas powered electric generator with exhaust heat creating the equivalent of 3 kW of heating energy for hot water. Whenever there is a request for more hot water or reheating existing tank water then the electric generator is in operation. Centralised plants can supply electricity and heat to multiple users or buildings. Environmental benefits include avoiding distant large power plants wasting heat to the environment and then having transmission losses to get to you. In this instance around two thirds of input energy is wasted. This type of technology is used in Demark, The Netherlands, UK and Australia. Tri-generation also can use the heat for cooling purposes with absorption chillers for further benefits. Absorption chiller cooling can source energy from solar thermal energy for part of the day. The UK borough of Woking now generates 80% of its own power by having over 60 co-generation and tri-generation plants. In Australia Crown Casino now saves $360,000 per year in energy costs (see references).

Suggestions:

Would suit apartment / hotel buildings and centralised hot water.

Suggestions:

Would suit apartment / hotel buildings and centralised hot water.

Related Sections: Hot Water

References for further information 40 41 42 43 130 133 134

Table of Contents Reference Links